EM Simulation

PRODUCTS AND SERVICES

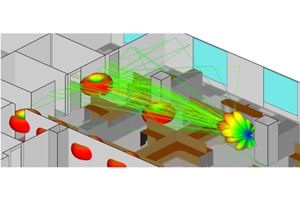

Wireless InSite® is a predictive tool for understanding wireless coverage, channel multipath, and data throughput for 5G, 6G, and WiFi networks.

Electromagnetic simulation saves time and money. Remcom Consulting is an ideal solution for those organizations that need an electromagnetic expert without an ongoing need for in-house electromagnetic modeling software.

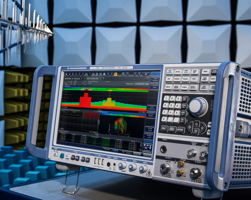

Rohde & Schwarz provides a range of customizable EMC test systems that deliver turnkey automated execution of EMC measurements to meet demanding requirements. As an industry leader for EMI test receivers and broadband amplifiers, Rohde & Schwarz has all the core components required to assemble a complete system.

Determining the final set of component values in a matching network can be a challenging process. Traditionally, RF engineers have had to simplify and idealize their matching circuits in schematics that are separated from the EM simulation. This simplification into a lumped element schematic requires perfect grounds and leaves out the coupling and transmission line effects of the interconnect metal and the antennas.

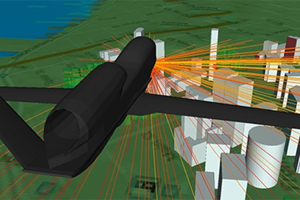

Design requirements for 24 GHz and 77 GHz automotive radar sensors are becoming more stringent as consumers increase demand for applications like blind spot detection (BSD) and lane change assistance (LCA). In turn, the engineering departments at Tier 1 suppliers like Delphi, Autoliv, and Continental are advancing technology in order to win bids from OEMs like BMW, Audi, and Chrysler.

Simulation technology has also advanced to meet design requirements. Remcom offers an integrated approach from sensor design to drive test scenarios.

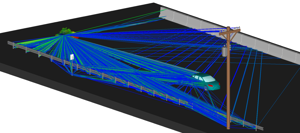

WaveFarer® is a high fidelity radar simulator that accounts for multipath and scattering from structures and vehicles in the immediate environment of a radar system as well as key atmospheric and scattering effects for frequencies up to and beyond 100 GHz.

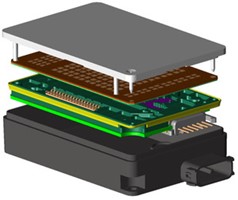

The ArchiTek™ FPGA Development Suite is designed to allow FPGA design engineers to add custom IP to a number of Pentek's Talon recording systems. FPGA IP can be added to the recorder to provide real-time, on-the-fly digital signal processing during the data acquisition process, greatly reducing the time associated with post-processing recorded data. ArchiTek provides a simple development environment that allows engineers to add FPGA IP such as threshold detection, spectral filtering, digital downconversion, demodulation, or any other digital signal processing technique required.

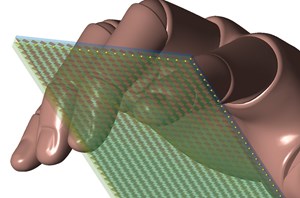

XFdtd can compute the capacitance of complex sensor designs, allowing the designer to choose the best geometry for their needs without prototyping.