Thermal and Electromagnetic Modeling Combined in Flomerics' Latest Software -- An Industry First

Design engineers will be able to simultaneously conduct thermal and electromagnetic analysis for the very first time

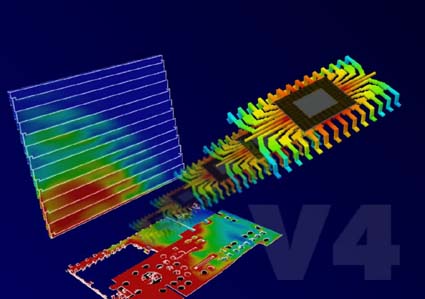

Electronic Design Engineers can now for the very first time simultaneously conduct thermal and electromagnetic analyses -- two design issues that impact on one another -- using the latest Flotherm and Flo/EMC v4.1 software from Flomerics. In addition to this groundbreaking capability, which will significantly reduce time-to-market for electronics companies, Flotherm v4.1 incorporates a number of other important enhancements including automatic sequential optimization, multi-level nested grids (this alone can reduce software calculation times ten-fold), and the ability to conduct thermo-mechanical stress calculations in order to predict reliability directly.

During the design process, design engineers must ensure that electronic systems meet both thermal and electromagnetic compliance (EMC) standards. Until now, engineers have been forced to tackle these issues sequentially. This presents a challenge as thermal and EM issues are inextricably linked -- adding screens, gaskets, etc in order to improve EM compliance may adversely affect the system's thermal performance, and vice-versa. Using Flotherm and Flo/EMC v4.1, however, it is possible to transfer information between the two packages in real time, and assess the impact of design changes immediately. Ian Clark, Flotherm Product Manager, commented, "This new capability is undoubtedly a major step forward in the physical design of electronics. This will be very popular with design engineers as it will help them quickly arrive at an optimized design, rather than being 'bounced around' the design space dealing with thermal and EMC issues separately."

Further accelerating the design cycle is Flotherm v4.1's 'automatic sequential optimisation' capability. This new feature allows users to specify a design aim -- for example, to minimize the operating temperature of a particular component -- and then to tell the software which items surrounding this component can be adjusted to optimize the cooling. The design is then optimized intelligently by the software using the minimum number of simulations, thereby saving an enormous amount of manual effort.

Another brand new feature is the "multi-level nested grid," which reduces calculation times by up to ten-fold and -- for the first time ever -- allows temperatures inside individual critical components to be calculated as part of a system-level analysis.

The Flo/STRESS module, which calculates thermomechanical stresses within solid components, has also been updated alongside Flotherm v4.1. This module now allows for the effects of "plastic" deformations within solids, and is therefore able to identify likely failure sites within components and joints, as well as the number of cycles to failure -- the most common being solder joint failure and the failure of vias in the board.

Other time saving features new to Flotherm v4.1 include:

- 'Drag and drop' library manager that makes the creation and use of a model library easier than ever before.

- Intelligent import of PCB data from EDA software, including locating matching library models for components and placing them on the board automatically.

- Direct import of "native" geometry from MCAD software such as Pro/ENGINEER and without loss of model integrity.

Ian Clark, Flotherm Product Manager, Flomerics, concludes, "The enhancements seen in Flotherm v4.1 provide software simulation techniques that have never before been possible in the electronics design industry. The combination of Flotherm and Flo/EMC v4.1 allows engineers to work coherently with multiple areas of the design process that, until now, have been viewed as separate entities. This will have a huge impact on the way design engineers work in the future."

Bruce Fryers, Mechanical Design Manager at 3Com UK - a leading supplier of networking equipment – commented, "Flomerics strategy of linking its EMC and thermal analysis software makes the use of it much simpler and therefore open to wider use in electronic design. In my experience there are many occasions when thermal and EMC design changes impact each other, therefore anything which makes it easier to solve these inter-related design problems is good news. At 3Com we are long-term users of Flomerics' thermal software, Flotherm, and more recent users of the Flo/EMC simulation tool. We have previewed the new integrated software intensively and we are very much looking forward to getting our hands on it."