Rectangular Or Circular, There's More To Connectors Than Meets The Eye

By John Oncea, Editor

Two common types of connectors are rectangular and circular, both of which can be used in various applications. In addition to differing in shape, these two types of connectors differ in contact density, durability, installation methods, and ideal applications as well. Choosing between the two depends on factors such as space constraints, environmental conditions, contact density requirements, and ease of installation.

Connectors are a crucial part of any electrical system, helping to improve overall performance and reliability. They can significantly affect signal integrity, especially in high-frequency applications or systems with sensitive signals. Poorly chosen connectors can introduce noise, signal degradation, or even signal loss, leading to system failures. A system’s reliability depends on its components’ reliability, including connectors which, if they fail prematurely or intermittently, can lead to costly downtime or damage to the device.

Choosing connectors is often an afterthought and many times results in the use of cheaper or incompatible components to save money. However, this can lead to higher long-term expenses due to increased maintenance, replacement, or system failures.

Like the rest of the system, connectors should be selected with future scalability in mind. If the system needs to be expanded or modified later on, having appropriate connectors in place can simplify the process and minimize downtime. Using standardized connectors ensures compatibility with existing equipment and reduces integration challenges.

Well-chosen connectors can optimize the performance of the entire system. This includes minimizing signal loss, reducing crosstalk, and matching impedance. It also will facilitate easier maintenance and troubleshooting, and clearly labeled connectors make it simpler to identify and rectify issues when they arise.

In certain industries, such as medical devices or aerospace, regulatory compliance is essential. Connectors may need to meet specific standards for safety, electromagnetic compatibility (EMC), or other regulatory requirements.

Common Connectors, Various Applications

There are two main types of connectors, namely rectangular and circular. Both are versatile and can be used in various applications and, apart from the difference in shape, these two types of connectors differ in contact density, durability, installation methods, and ideal applications as well. The choice between the two types of connectors depends on several factors such as space constraints, environmental conditions, contact density requirements, and ease of installation.

Providers of connectors such as HUBER+SUHNER, MegaPhase, and Times Microwave Systems note some of the following differences between rectangular and circular connectors:

- Shape and Design

- Rectangular connectors have a box-like shape with straight edges and typically consist of multiple pins or sockets arranged in rows and columns.

- Circular connectors, as the name suggests, have a circular shape and are usually composed of cylindrical housing with pins arranged around the circumference.

- Contact Density

- Rectangular connectors often have a higher contact density due to their grid-like arrangement of pins or sockets, allowing for more connections in a given space.

- Circular connectors usually have lower contact density because the pins are arranged around the circumference, limiting the number of contacts that can be accommodated.

- Durability

- Rectangular connectors can vary in durability depending on their design and materials used, but they may not always offer the same level of ruggedness as circular connectors.

- Circular connectors are generally more robust and resistant to environmental factors such as moisture, dust, and vibration, making them suitable for harsh conditions.

- Installation and Mating

- Rectangular connectors typically require screws or latches for mating, which may take slightly longer but can offer a more secure connection in certain applications.

- Circular connectors often feature a bayonet or threaded coupling mechanism, allowing for quick and secure mating without the need for tools.

- Versatility

- Rectangular connectors are commonly used in applications where space is limited or where a high contact density is required, such as in computer hardware, automotive electronics, and industrial control systems.

- Circular connectors are preferred in applications where durability and resistance to harsh environments are essential, such as aerospace, military, and outdoor industrial applications.

- Ease of Termination

- Rectangular connectors may have a more complex termination process, especially for high-density connectors with numerous pins.

- Circular connectors may have easier termination options due to the circular layout of contacts, which can facilitate soldering or crimping.

- Customization and Special Features

- Both types of connectors can be customized to include special features such as locking mechanisms, shielding, and sealing for specific application requirements.

Rectangular Connectors: High-Power, Multi-Use

Rectangular connectors, also known as rectangular electrical connectors, are a type of electrical connector commonly used in various industries to facilitate the connection and disconnection of electrical circuits. As the name suggests, they have a rectangular shape and typically consist of a male and female component that mate together to establish an electrical connection. The following are key aspects and features of rectangular connectors:

- Shape and Size: Rectangular connectors come in various shapes and sizes, ranging from small, compact connectors used in consumer electronics to large, heavy-duty connectors used in industrial applications. The rectangular shape allows for efficient use of space and easy integration into equipment and systems.

- Materials: These connectors are typically constructed from materials such as metal, plastic, or a combination of both. The choice of materials depends on factors such as the application environment, required durability, and electrical properties.

- Contacts: Rectangular connectors contain metal contacts that make electrical connections when the male and female components are mated together. These contacts can vary in design, including pin contacts, socket contacts, or a combination of both.

- Termination Methods: There are various termination methods for rectangular connectors, including soldering, crimping, and insulation displacement. The choice of termination method depends on factors such as the application requirements, ease of assembly, and reliability.

- Locking Mechanisms: Many rectangular connectors feature locking mechanisms to ensure a secure connection between the male and female components. These mechanisms can include screws, latches, clips, or other types of fasteners.

- Application: Rectangular connectors find applications in a wide range of industries, including aerospace, automotive, telecommunications, industrial automation, medical devices, and consumer electronics. They are used for power transmission, signal transmission, data communication, and control purposes.

- Modularity: Some rectangular connector systems offer modular designs, allowing users to customize the connector configuration by adding or removing modules according to their specific requirements. This modularity enhances flexibility and scalability in system design.

- Environmental Protection: In certain applications where exposure to harsh environments is a concern, rectangular connectors may feature additional sealing or shielding to protect against dust, moisture, vibration, and electromagnetic interference (EMI).

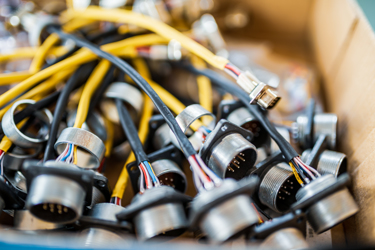

Circular Connectors: Compact And Streamlined

Circular connectors are a type of electrical connector characterized by their cylindrical shape, which allows for a secure and reliable connection between two electrical devices. These connectors are widely used in various industries, including aerospace, military, telecommunications, automotive, and industrial applications. Here are some key aspects of circular connectors:

- Design and Construction: Circular connectors consist of a male plug and a female receptacle. The plug typically has pins or male contacts, while the receptacle has corresponding sockets or female contacts. The cylindrical housing of the connector provides protection and mechanical stability.

- Materials: Circular connectors can be made from various materials, including metals like aluminum, stainless steel, or brass for the housing, and conductive materials like copper or gold for the contacts. These materials are chosen based on factors such as conductivity, durability, and environmental resistance.

- Size and Configuration: Circular connectors come in a range of sizes and configurations, from miniature connectors with just a few contacts to large connectors with dozens of contacts. The size and configuration depend on the specific application requirements, such as the number of signals to be transmitted and the space available for the connector.

- Termination Methods: Circular connectors can be terminated using different methods, including soldering, crimping, or screw terminals. The choice of termination method depends on factors such as ease of assembly, reliability, and serviceability.

- Keying and Polarization: To prevent incorrect mating and ensure proper alignment of the contacts, circular connectors often feature keying and polarization mechanisms. These mechanisms ensure that the plug can only be inserted into the receptacle in the correct orientation.

- Environmental Protection: Circular connectors are designed to withstand harsh environmental conditions, including moisture, dust, vibration, and temperature extremes. Many connectors feature sealing gaskets or O-rings to protect against moisture and dust ingress. Additionally, connectors intended for use in extreme environments may be rated for specific environmental standards such as IP (Ingress Protection) or MIL-STD (Military Standard).

- Quick Disconnect: Circular connectors often feature a quick-disconnect mechanism, allowing for easy and rapid connection and disconnection of devices. This feature is particularly useful in applications where frequent mating and unmating of connectors are required, such as in field installations or maintenance procedures.

- Applications: Circular connectors are used in a wide range of applications, including:

- Aerospace and aviation: for avionics, in-flight entertainment systems, and communication equipment.

- Military and defense: for military vehicles, weaponry, communication systems, and rugged equipment.

- Industrial automation: for machinery, sensors, actuators, and control systems.

- Automotive: for vehicle electronics, sensors, and lighting systems.

- Medical devices: for diagnostic equipment, patient monitoring systems, and imaging devices.

Rectangular and circular connectors are essential components in many electronic and electrical systems, providing a reliable and durable means of connecting and transmitting signals in diverse applications. They are crucial in facilitating electrical connections in a wide range of applications, offering versatility, reliability, and robustness to meet diverse engineering requirements.