Tutorial On Oven Controlled Crystal Oscillators (OCXOs)

By Vectron International

If stability requirements are too stringent to be met by a basic crystal oscillator or temperature compensated crystal oscillator (TCXO), the crystal and critical circuits may be temperature controlled by an oven. The block diagram for a Vectron oven controlled crystal oscillator (OCXO) is similar to that for a Vectron TCXO except that the varactor diode and associated thermistor compensation network are deleted and the oscillator is instead temperature controlled by a proportionally controlled oven.

Proportional Oven Controlled

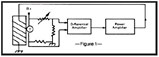

A proportional control is an electronic servo system which continuously supplies power to the oven; it varies the amount of oven power, continuously compensating for the ambient temperature changes. In many Vectron oven controlled oscillators, a thermistor is heat sunk to the oven's metal shell to sense temperature. The thermistor is one leg of a resistance bridge, as shown in the following diagram.

The bridge operates such that if the temperature at the oven decreases due to an ambient temperature change, the change in thermistor resistance causes the bridge to unbalance, developing an increase in bridge output voltage. This voltage is amplified in a high-gain differential amplifier. The output of the differential amplifier is further amplified in a power amplifier which drives directly into the oven winding. Thus, the small voltage increase resulting from bridge unbalance generates a large voltage increase across the oven winding. This increase in power to the oven generates more heat, compensating for the temperature decrease which was initially sensed by the thermistor. Similarly, an increase in temperature at the oven causes a reduction in bridge output voltage, which results in reduced power into the oven and a compensating temperature decrease.

Click here to download the complete application note in pdf format.