Multicoax Board-Mounted Connector Performs To 90 GHz

Discover essential specifications and recommendations for the successful assembly of the MXPM PCB Socket, a high-performance RF connector system. Strict adherence to the assembly process specifications is necessary to achieve the full rated electrical performance of the semi-SMT design.

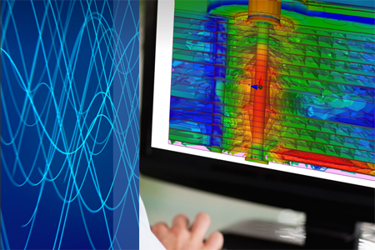

Key focus areas include footprint optimization, which is crucial for reliable production and requires matched impedance footprints for RF signals. Because footprints depend on the base material and PCB stack-up (relative dielectric constant, layer thickness, etc.), customization often necessitates electromagnetic 3D-field simulation for design. The document recommends using filled vias for the signal path, serving as transmissions into or through the layer stack-up. It is vital to procure impedance-controlled boards from experienced manufacturers.

Regarding materials, gold plating is an excellent choice for soldering, though caution against thick layers is advised as excessive gold diffusion into solder can render it brittle. Silver plating of traces can mitigate losses and enhance signal integrity.

For component placement, the MXPM sockets are fully compatible with standard pick-and-place systems and are supplied in tape and reel format, certified for Unlimited Floor Life (Level 1).

Crucially, soldering must be performed using industrial reflow equipment or a reliable rework station; soldering irons or hot air pencils are inappropriate. The note details the use of pin-in-paste technology for the guide pins, requiring a Type 3 solder grain size and a recommended solder paste/solder mask thickness of 150 µm. Specific guidelines are provided for pin protrusion (maximum 1.5 mm) and adjusting visual inspection procedures when guide pins extend beyond the PCB surface.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of RF Globalnet? Subscribe today.