MMIC Technologies: Integrated Passive Devices (IPD)

By Radha Setty, Technical Advisor

Monolithic Microwave Integrated Circuits (MMICs) with no active elements such as transistors, and containing only passive elements such as resistors, capacitors, inductors, are referred to as Integrated Passive Devices (IPD). These devices do not need DC power to operate, and do not perform frequency conversion as in the case of frequency mixers or frequency multipliers.

What’s the big deal about IPDs? The short answer is they perform vital functions which active elements cannot such as filtering, equalization, balanced-to-unbalanced line conversion (or vice versa) and many more as we will describe later. IPD brings all the advantages of continuously evolving MMIC technology developed for high volume applications like computers and cell phones to passive devices which were traditionally implemented with larger, more expensive technologies such as thin film. In short IPD’s are:

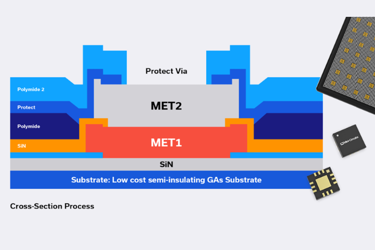

- Small – The use of lumped components at low frequency and clever layout techniques at high frequency like multiple metal layers and on-chip interconnects result in extremely small device size.

- Repeatable – Thanks to amazing advances in MMIC manufacturing, on-chip components can be manufactured with remarkable precision.

- Highly reliable – Intensive R&D and innovations in MMIC manufacturing have achieved low-defect or defect-free processes. MMIC manufacturing foundries set design rules based on reliability studies and manufacturing capability which results in high yield. Mini-Circuits designers follow design rules provided by the MMIC foundry to eliminate manufacturing defects.

- Low cost – MMIC manufacturing takes place in a clean room environment using automated equipment. Foundries can manufacture a large number of wafers in a short time with high yield. Mini-Circuits designers minimize die size using lumped components and clever layouts resulting in a large number of die per wafer, and therefore lower cost per die. Packaging and testing are performed using robots and automated systems for high throughput and lower overall production cost.

- Available in packaged or die form – Die are used by hybrid circuit manufactures utilizing chip and wire assembly. The variety of die in the market is limited, but Mini-Circuits offers the majority of its MMICs, including IPD designs, in wafer form or as singulated die for such users [7] and as a stock item for rapid prototyping and production. Packaged die enable automated pick-and-place manufacturing at the user end.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of RF Globalnet? Subscribe today.