Utilizing Modern Day MPMs For High-Power And High-Efficiency

By Jose Gonzales, dB Control

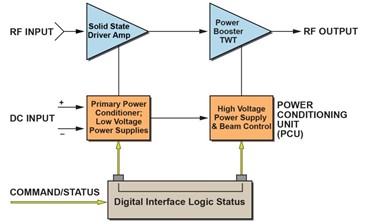

The first MPM, developed in the early 1990s, used a solid-state driver amplifier, based on MMICs or discrete RF power transistors, to drive a mini traveling-wave tube (mini-TWT), and combined these devices with a power supply and control circuits in a very compact enclosure.

Today’s MPMs follow the same concept. The RF signal path consists of a solid-state driver amplifier and a short-length booster TWT (typically about seven inches long), specifically designed for use with a lower-voltage power supply (up to 8 kV). The gain reduction that occurs from shortening the TWT helix length is compensated by the driver amplifier, and the gain in the RF chain is maintained. The power-handling capability, bandwidth, efficiency, and heat-tolerance capability of the TWT is fully utilized in this design.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of RF Globalnet? Subscribe today.