High-Density PC Board Assemblies For Defense, Aerospace, And Commercial Applications Introduced

Endicott, NY -- Large, high complexity PC boards for use in compute-intensive applications such as servers and mainframes for defense, aerospace, and commercial applications are available from assembly solutions specialist Endicott Interconnect (EI) Technologies, Inc.

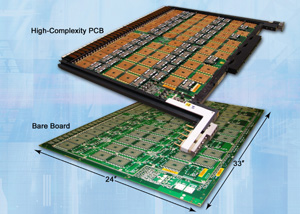

Endicott, NY -- Large, high complexity PC boards for use in compute-intensive applications such as servers and mainframes for defense, aerospace, and commercial applications are available from assembly solutions specialist Endicott Interconnect (EI) Technologies, Inc.EI can provide high-density, double sided, hybrid PC board assemblies (SMT/PTH/press fit) with an average component count of > 1500, including high-I/O area array modules (CGA, LGA, PBGA) and dense, high-I/O connectors, in sizes as large as 32" x 44".

"These are very large, complex boards with high I/O count BGAs, a lot of SMT and press fit connectors, and on-board through-hole soldered power supplies," said Stephen Howland, Product Manager of EI Complex Assembly Operations. "They are for customers who require a lot of processing power and a lot of memory."

Endicott Interconnect provides the capability of going from bare board to a complex PC board assembly that is finished, populated and fully tested. "Our ability to populate and test boards this large is fairly unique," said Howland. "A 24" x 36" board might have as many as 100 BGA attached devices on one side."

EI's full hybrid assembly capabilities can provide a wide range of PC board assemblies from high-end, complex, mission critical to lower complexity, depending on customer requirements.

"We manufacture the raw board and then assemble it to customer specifications," said Vic Barba, Director of Engineering for Complex Assembly Operations. "A typical build cycle from fab to finished board is approximately 2 weeks."

EI has spent $7 million in capital equipment, including 6 new assembly lines in the past 12 months, to meet the increased demand for its large, complex, PC board assemblies. The company offers the smallest flip chip placement available, and now has the ability to place components as small as 10 mils x 5 mils.

SOURCE: Endicott Interconnect Technologies, Inc.