A Q&A On Thin Film Circuit Technology

By Peter Matthews

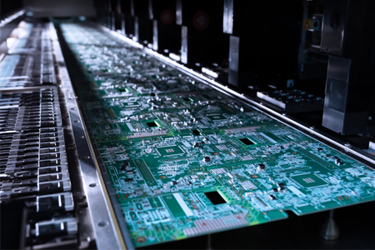

Thin-film circuit technology involves depositing ultra-thin material layers, from fractions of a nanometer to several micrometers, onto ceramic substrates to create high-performance electronic components. This method is particularly advantageous for RF and microwave devices, offering excellent high-frequency performance, compact size, and enhanced stability and reliability.

When selecting a thin-film circuit manufacturer, prioritize those with expertise in custom circuit production and build-to-print capabilities. These manufacturers can adapt to specific design requirements and ensure quality through comprehensive testing, from prototypes to final production.

Thin-film technology excels in creating filters with low passband insertion loss, high rejection, and superior temperature stability. These attributes make thin-film filters ideal for space-constrained systems that demand high-frequency precision. Thin film is also highly effective in constructing interposers and Integrated Passive Devices (IPDs). Thin-film interposers offer reduced signal loss and advanced packaging options, including heterogeneous integration, while IPDs consolidate numerous components into a single, space-saving device. This minimizes assembly time and improves performance, provided the components are properly assembled.

Knowles Precision Devices specializes in applying thin-film technology for military and aerospace applications. Their proven processes ensure reliable performance, even in harsh environments, by producing compact, high-quality components tailored to specific requirements. Thin-film circuits are critical for high-frequency applications requiring exceptional precision, reliability, and space efficiency, making them a valuable solution for cutting-edge technologies.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of RF Globalnet? Subscribe today.