EM Simulation

PRODUCTS AND SERVICES

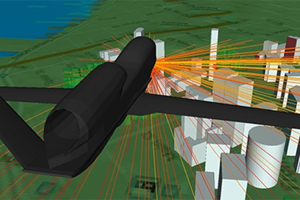

Wind turbines located near a radar installation can significantly interfere with the ability of the radar to operate properly. Remcom provides radar scattering expertise for government-funded research efforts into the impact that wind turbines and wind farms have on radar returns for Air Traffic Control (ATC) radar, early warning radar, weather radar, and instrumentation radar.

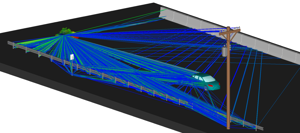

WaveFarer® is a high fidelity radar simulator that accounts for multipath and scattering from structures and vehicles in the immediate environment of a radar system as well as key atmospheric and scattering effects for frequencies up to and beyond 100 GHz.

Electromagnetic simulation saves time and money. Remcom Consulting is an ideal solution for those organizations that need an electromagnetic expert without an ongoing need for in-house electromagnetic modeling software.

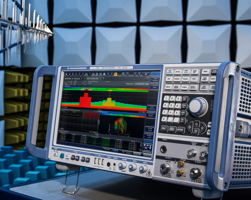

Rohde & Schwarz provides a range of customizable EMC test systems that deliver turnkey automated execution of EMC measurements to meet demanding requirements. As an industry leader for EMI test receivers and broadband amplifiers, Rohde & Schwarz has all the core components required to assemble a complete system.

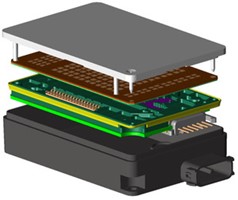

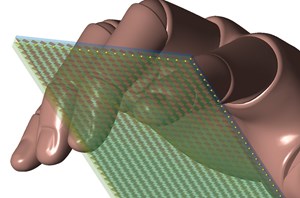

Electrostatic discharge testing is utilized worldwide by electronics manufacturers to determine the ESD susceptibility of their devices. It is extremely difficult to estimate the exact cost of ESD loss annually, but it can safely be stated that ESD requires the development and testing of many hardware prototypes and contributes to a high number of warranty claims and loss of consumer confidence if failure occurs in the hands of the customer. Given the high cost in time and materials associated with ESD hardware testing, the ability to simulate the ESD testing process in XFdtd is extremely valuable, allowing engineers to pinpoint locations susceptible to ESD damage and optimize ESD mitigation during the concept and design stage of product development.

Design requirements for 24 GHz and 77 GHz automotive radar sensors are becoming more stringent as consumers increase demand for applications like blind spot detection (BSD) and lane change assistance (LCA). In turn, the engineering departments at Tier 1 suppliers like Delphi, Autoliv, and Continental are advancing technology in order to win bids from OEMs like BMW, Audi, and Chrysler.

Simulation technology has also advanced to meet design requirements. Remcom offers an integrated approach from sensor design to drive test scenarios.

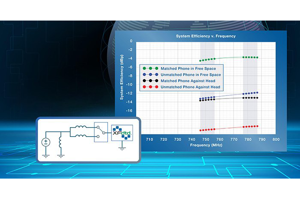

Remcom’s XFdtd EM Simulation Software offers unique capabilities to help engineers navigate antenna design challenges with speed and accuracy.

XFdtd can compute the capacitance of complex sensor designs, allowing the designer to choose the best geometry for their needs without prototyping.